.

RUBBER ROADSAsphalt recycling with tires, more than just environmental benefits.

At the moment it is something experimental and there are only a few stretches of road paved with tires out of use (N-FU), about 200 kilometers in total, according to the Center for Studies and Experimentation of Public Works (CEDEX). The first date from 1994, although most have been built

At the moment it is something experimental and there are only a few stretches of road paved with tires out of use (N-FU), about 200 kilometers in total, according to the Center for Studies and Experimentation of Public Works (CEDEX). The first date from 1994, although most have been built  since 2001. Currently, everything seems favorable for the definitive takeoff of the “rubber roads”: since July, a law prohibits the dumping of NFU and obliges manufacturers to collect them and, at the same time, the Ministries of Development and Environment In collaboration with CEDEX, they have completed the “Use Manual for Rubber from NFU in Bituminous Mixtures” and plan to build a series of sections where they can study how these mixes behave depending on the technique used, the traffic or the weather. “The technical feasibility is already verified or through the experimental sections -says Jose Maria Bermejo, technical director of Signus, one of the companies responsible for the collection of the NFU-, but the positions (in the Administration) are rather conservative and prudent and the specifications of technical prescriptions take time to get underway”. Juan Antonio Tejala, public works engineer and director of RENECAL, a recycling company, confirms: “This is just beginning, the percentage of used road tires It’s still low.”

since 2001. Currently, everything seems favorable for the definitive takeoff of the “rubber roads”: since July, a law prohibits the dumping of NFU and obliges manufacturers to collect them and, at the same time, the Ministries of Development and Environment In collaboration with CEDEX, they have completed the “Use Manual for Rubber from NFU in Bituminous Mixtures” and plan to build a series of sections where they can study how these mixes behave depending on the technique used, the traffic or the weather. “The technical feasibility is already verified or through the experimental sections -says Jose Maria Bermejo, technical director of Signus, one of the companies responsible for the collection of the NFU-, but the positions (in the Administration) are rather conservative and prudent and the specifications of technical prescriptions take time to get underway”. Juan Antonio Tejala, public works engineer and director of RENECAL, a recycling company, confirms: “This is just beginning, the percentage of used road tires It’s still low.”

NOTHING NEW. Actually, it is not something new. Tire-modified asphalts were in use in the United States more than 60 years ago. Over time, the mixtures improved and, for example, in the 1960s an asphalt mixture with rubber resistant to wheels with nails and chains was developed in Sweden, which was later also taken to roads in Alaska and other North American states.

NOTHING NEW. Actually, it is not something new. Tire-modified asphalts were in use in the United States more than 60 years ago. Over time, the mixtures improved and, for example, in the 1960s an asphalt mixture with rubber resistant to wheels with nails and chains was developed in Sweden, which was later also taken to roads in Alaska and other North American states.

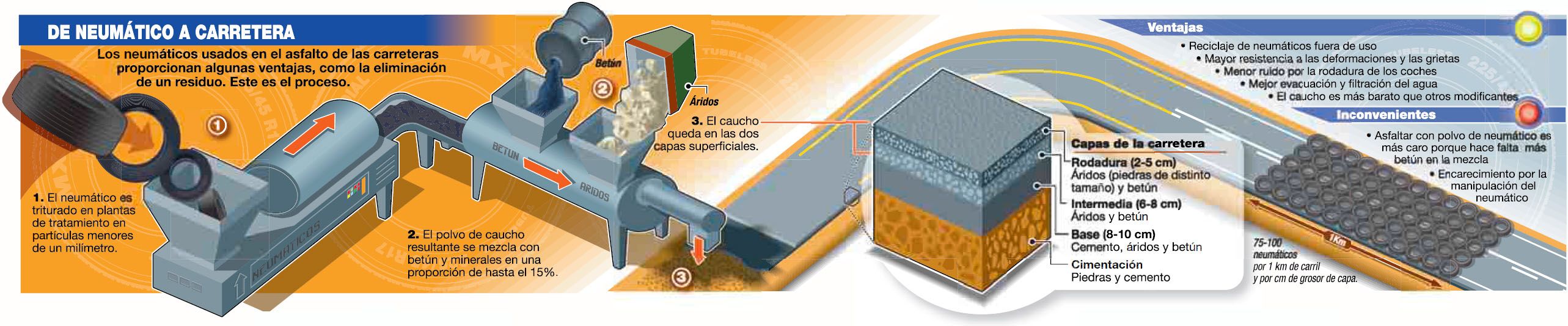

The star ingredient of these “rubber roads” is the rubber, which is obtained in a simple way: once collected, the used tires are transported to treatment plants where they are broken down; the rubber – half the weight of the tire – is separated from the metal and textile parts and crushed until it is reduced to particles no larger than one millimeter. The result is rubber powder that, added to bitumen (the “glue” in road construction) and to aggregates (sand and stones), provides better asphalt than conventional asphalt. Currently, millions of tons of NFU are used in the construction of roads in Portugal, Greece, Italy, USA, Russia or China. Spain generates some 300,000 tons of NFU per year – the fifth country in the EU – and it seems that the best way to dispose of this waste is to return it to the road as a construction material. This is what Jaime Alejandre, general director of Environmental Quality of the Ministry of the Environment, believes: “We will no longer see those mountains of used tires in landfills – he assures. Only 10% is recycled, our goal is to recycle all of them in 2 or 3 years and dedicate 70% to roads. It’s the best way out.”

The star ingredient of these “rubber roads” is the rubber, which is obtained in a simple way: once collected, the used tires are transported to treatment plants where they are broken down; the rubber – half the weight of the tire – is separated from the metal and textile parts and crushed until it is reduced to particles no larger than one millimeter. The result is rubber powder that, added to bitumen (the “glue” in road construction) and to aggregates (sand and stones), provides better asphalt than conventional asphalt. Currently, millions of tons of NFU are used in the construction of roads in Portugal, Greece, Italy, USA, Russia or China. Spain generates some 300,000 tons of NFU per year – the fifth country in the EU – and it seems that the best way to dispose of this waste is to return it to the road as a construction material. This is what Jaime Alejandre, general director of Environmental Quality of the Ministry of the Environment, believes: “We will no longer see those mountains of used tires in landfills – he assures. Only 10% is recycled, our goal is to recycle all of them in 2 or 3 years and dedicate 70% to roads. It’s the best way out.”

For their part, the environmental groups agree to give a second life to the NFU, not only in the construction of roads, but also as shoe soles, anti-noise screens, sports courts, artificial grass fields, or tiles of safety for playgrounds: “We are in favor, they are too valuable and their manufacture is expensive to end up as fuel in cement and other factories,” says Leticia Baselga, responsible for the Waste Area of Ecologistas en Acción.

For their part, the environmental groups agree to give a second life to the NFU, not only in the construction of roads, but also as shoe soles, anti-noise screens, sports courts, artificial grass fields, or tiles of safety for playgrounds: “We are in favor, they are too valuable and their manufacture is expensive to end up as fuel in cement and other factories,” says Leticia Baselga, responsible for the Waste Area of Ecologistas en Acción.

All the experts consulted agree on the advantages of modified asphalt compared to conventional asphalt. “It’s another world,” says the head of production at Asfaltos Uribe, in Vizcaya, but he warns: “Between modifying asphalt with tires or with other additives, there are no big differences.” According to Baltasar Rubio, from the CEDEX Center for Transportation Studies, the asphalt with rubber “it releases the NFU, but also greater resistance (depending on the mixture), makes less noise and is more resistant to cracks”, although he admits that “not many differences have been seen with other modified asphalts”. From the Ministry of Public Works they affirm that the mixtures of bitumen and rubber “have no drawbacks from the point of view of adherence and road safety”, although “they reduce yields, because mixing and compaction times are longer” and they are “more expensive than traditional ones” due to the extra cost of tire dust and because they require more bitumen. This happens because the rubber is very abundant, so the ton of asphalt becomes more expensive from 3 to 5€. Despite this, for Juan Antonio Tejela it is profitable, because “rubber mixtures are very flexible and extend the useful life of roads, so instead of renewing them every 10 years, they do it every 15 with tires.”