Light sheets made up of tiny LEDs

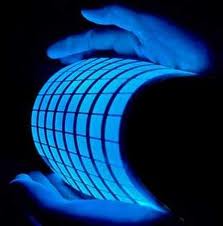

Nth Degree Technologies plans to replace light bulbs with lights that can be printed on large flexible surfaces.

.

A company called Nth Degree Technologies aims to replace traditional light bulbs with a material similar to luminous paper. At the end of this year, this company plans to send its first commercial product to a group of selected clients: a rectangular lamp measuring 60×120 centimeters.

A company called Nth Degree Technologies aims to replace traditional light bulbs with a material similar to luminous paper. At the end of this year, this company plans to send its first commercial product to a group of selected clients: a rectangular lamp measuring 60×120 centimeters.

This technology would allow the creation of novel lamp designs at a cost comparable to the standard and fluorescent light bulbs in use today, says Neil Shotton, president and CEO of Nth Degree. Light could be emitted from very large areas, with curved surfaces or unusual shapes. The printing processes used to make the lights also make it very easy to vary the color and intensity of the light emitted. “It’s a new kind of lighting,” says Shotton.

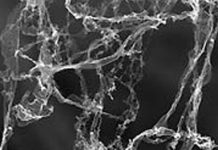

To make its light sheets, Nth Degree starts by carving a gallium nitrate wafer to produce millions of tiny LEDs (a 10-centimeter wafer contains about eight million). The LEDs are then mixed with resins and binders and a standard screen printer is used to deposit the resulting ‘ink’ over a large area.

In addition to the LED ink, a layer of silver ink is used to include the electrical contact on the back, a layer of phosphors to change the color of the light emitted by the LEDs (ranging from blue to various shades of white), and an insulating layer that prevents short circuits from occurring between the front and back. The front electrical contact, which has to be transparent to allow light to pass through, is made using an ink containing metal wires so small they are invisible.

The new transparent electrical contact could itself become an important product for the replacement of indium-tin oxide (ITO) used, among others, in touch screens. ITO is fragile and cannot be printed, so it is not suitable for flexible displays. It can also be expensive, depending on the price of the Indian.

Although the devices developed by the company so far are much more efficient than incandescent bulbs, they are still not as efficient as fluorescent ones. They emit 20 lumens per watt, compared to 80 lumens per watt for standard fluorescents and 65 lumens per watt for compact fluorescents. A 60-watt light bulb from GE gets about 14 lumens per watt.

Although the devices developed by the company so far are much more efficient than incandescent bulbs, they are still not as efficient as fluorescent ones. They emit 20 lumens per watt, compared to 80 lumens per watt for standard fluorescents and 65 lumens per watt for compact fluorescents. A 60-watt light bulb from GE gets about 14 lumens per watt.

The efficiency of the lights has been slowly and steadily improving over the past few months, Shotton explains. The goal is to reach 50 lumens per watt for the first products and 75 lumens per watt for the following year, a figure comparable to many other LEDs. Currently, the best on the market achieve more than 200 lumens per watt.

Printing with inks made up of tiny functional LEDs produces a much brighter light than that achieved by affixing powders or thin films of electroluminescent material, two methods already used to make flat night lamps, the greenish backlights of digital clocks and more recently to illuminate large billboards in cinemas and theaters with a white backlight.

Printing with inks made up of tiny functional LEDs produces a much brighter light than that achieved by affixing powders or thin films of electroluminescent material, two methods already used to make flat night lamps, the greenish backlights of digital clocks and more recently to illuminate large billboards in cinemas and theaters with a white backlight.

Raghu Das, CEO of IDTechEx, a research company specializing in printed electronics, says such lights could end up being cheaper than the organic LEDs (OLEDs) that have just appeared on the market. OLED lights are expensive (a table lamp costs about $6,000) and have to be sealed inside rigid glass to protect organic molecules from air and water.

The new design also eliminates the need for bulky heat sinks that conventional LED lights require. Since the tiny LEDs are distributed in a thin layer, the lights don’t get hot, says Shotton. However, the advantage of not needing a heatsink is negated by the fact that LEDs require a substantial power source and to incorporate this the first lamp the company launches will have to be five centimeters thick, despite the fact that the light-emitting surface will be thin and flexible.

The new design also eliminates the need for bulky heat sinks that conventional LED lights require. Since the tiny LEDs are distributed in a thin layer, the lights don’t get hot, says Shotton. However, the advantage of not needing a heatsink is negated by the fact that LEDs require a substantial power source and to incorporate this the first lamp the company launches will have to be five centimeters thick, despite the fact that the light-emitting surface will be thin and flexible.

Source: Technology Review

.