.

Utilities of the CHEMICAL TACOThe chemical anchor is undoubtedly the solution when we want to support a considerable weight on the wall or ceiling or, also if we have to anchor robustly some element to the ground.

The ideal solution is chemical wad. A solution not too widespread among DIY enthusiasts. For this reason, today we want to talk about it.

Example that I have been given at work: Put some squares about 30cm or 40cm from the ground and on them a board on which a front-loading washing machine will go, in order to place a small cupboard under it for dirty clothes, this is a solution to take advantage of the small space we have in an outdoor patio.

Example that I have been given at work: Put some squares about 30cm or 40cm from the ground and on them a board on which a front-loading washing machine will go, in order to place a small cupboard under it for dirty clothes, this is a solution to take advantage of the small space we have in an outdoor patio.

It could also be to place a shelf above the washer and on it the dryer. Perhaps the most common example is hanging the outdoor air conditioner. These would be three cases in which we have to be sure that the strong brackets fixed to the wall are not going to come off. The chemical plug is easy to install, it can be found at any hardware store or building material store.

I will give some information about this product, so that you can assess its strength.

DESCRIPTION

PATTEX TQ 900 is an adhesive mortar based on Vinylester technology, suitable for the safe fixing of medium-high loads. It is a two-component product, fast curing, free of styrene, phthalates and solvents, which has excellent resistance on all construction materials, both hollow (brick, concrete blocks, masonry,…) and solid (concrete, stone, etc.). solid brick, etc.).

It is applicable on wet surfaces, and has great chemical resistance (resists corrosion and immersion).

It presents a European technical approval (option 7 for compact concrete), and also has a high fire resistance time (F120). The container design allows its application with a professional silicone gun (ratio 23:1) and ensures a perfect mixing ratio between the two components at all times.

FIELDS OF APPLICATION

- Fixings to withstand medium-high loads in stone, concrete, brick and construction materials in general, both solid and hollow.

- Anchors of threaded or corrugated dowels, rods, reinforcing bars, fastening systems, etc., both in hollow walls and in solid supports.

- Multitude of anchors in construction: antennas, awnings, railings, air conditioners, lighting elements, signs, street furniture, etc.

- Repair of mortars, finishes and filling of holes and cavities on site.

ADVANTAGE

- Applicable on wet surfaces Great Chemical Resistance.

- It has high fire resistance time (F120).

- Without smell. Free of styrene or other substances harmful to health.

- Applicable with a professional silicone gun (ratio 23:1).

- Perfect mixing ratio between the two components from the beginning to the end of the cartridge.

- The resin and the hardener are never in contact in the cartridge, avoiding contamination and hardening inside.

- Use of the entire content of the cartridge and can be reused again (replacing the static mixer).

- Perfect mix quality at all times. It is practically not necessary to discard product to obtain a homogeneous mixture.

- Fast curing.

- High product consistency, suitable for use in ceiling applications.

- Does not expand. Suitable for making anchors close to each other or close to the edge of the support.

- It can be used in a multitude of supports in construction. Does not corrode metals.

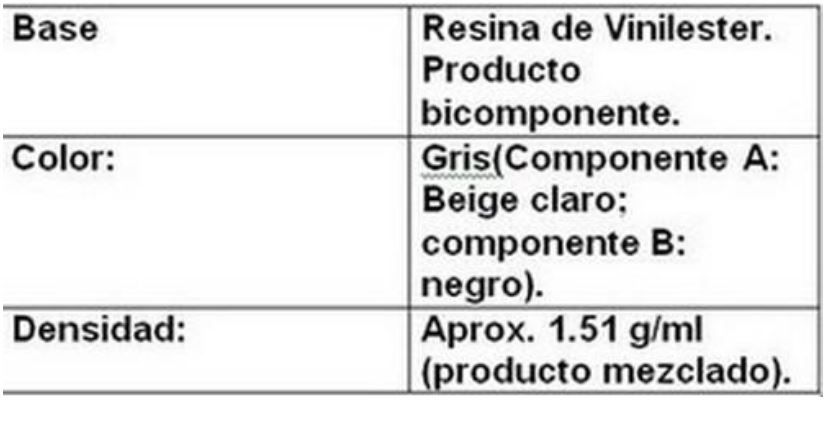

TECHNICAL DATA

INSTRUCTIONS FOR USE ON SOLID SUPPORT

Support preparation:

- The surface must be dry, clean and consolidated (without loose particles and complete setting of the concrete or mortar).

- Drill the indicated size (See table 1: “Parameters for placement on solid support”).

- Clean the dust hole by brushing or blowing with air.

- The metal parts to be anchored must be clean and free of grease, oil or rust.

APPLICATION OF THE CHEMICAL TACO:

- Remove the cap and screw on the static mixer.

- Put the cartridge in the gun. Press until a homogeneous gray color is obtained.

- Insert the nozzle to the bottom of the hole.

- Fill the hole from the bottom to the surface to approximately 2/3 of the same.

- Insert the element to be anchored turning it slowly to avoid the formation of air bubbles. If necessary, it should be held in place at first. The manipulation/adjustment of the anchor must be carried out before the curing start time. (See section Technical Data_Curing Time).

- Apply the load (See table 2: “Recommended resistance (kN) on solid support”), after the complete curing time (See Technical Data_Curing Time section).

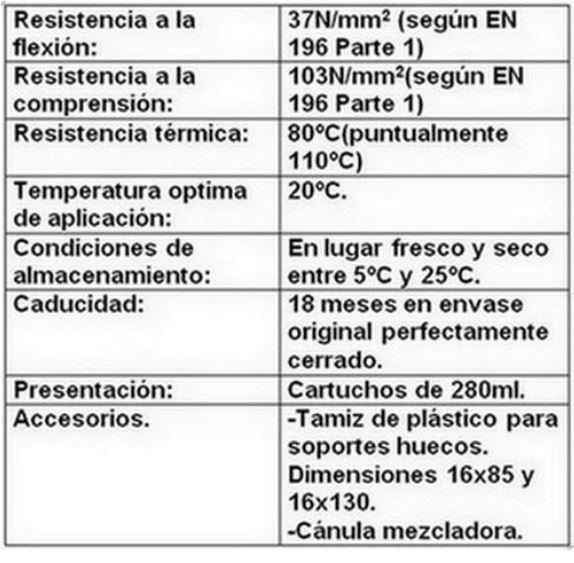

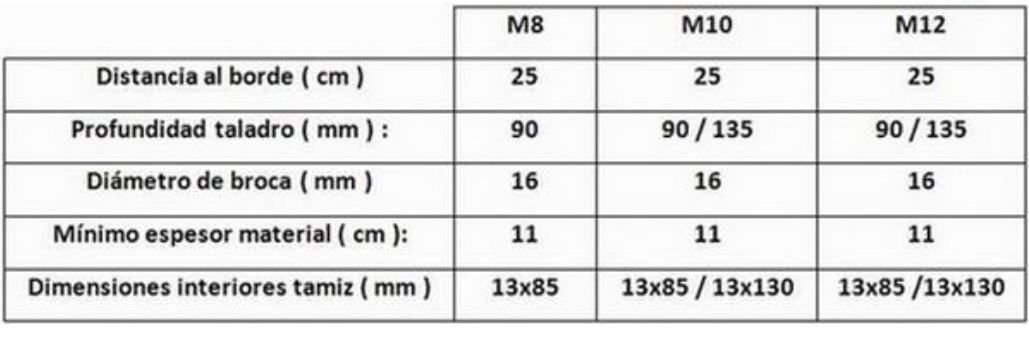

TABLE 1: PLACEMENT PARAMETERS ON SOLID SUPPORT TABLE

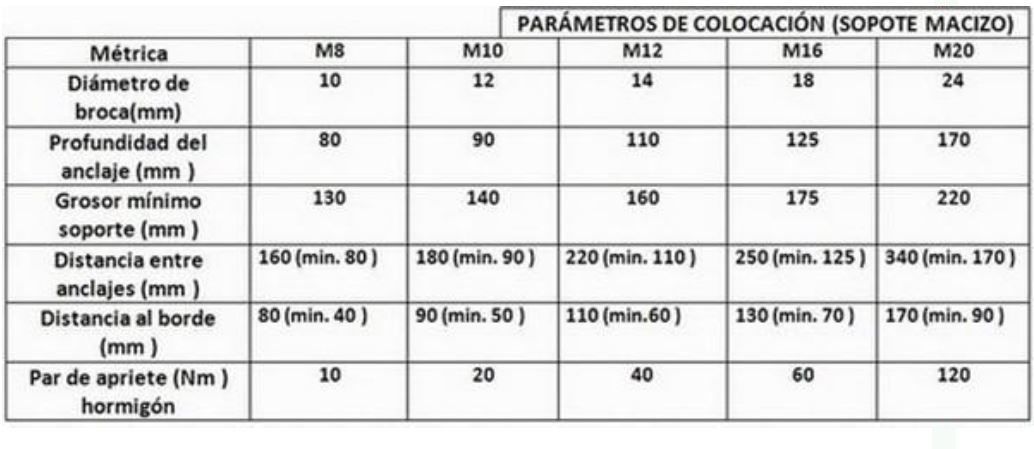

TABLE 2: RECOMMENDED RESISTANCE (kN) ON SOLID SUPPORT

Classification of Concrete according to DIN 1045 data valid for 5.8mm galvanized Zinc / A4-70 rod Note: 1kN = approx. 98Kg (strength)

INSTRUCTIONS FOR USE ON HOLLOW SUPPORT ON HOLLOW SUPPORT:

Support preparation:

- The surface must be dry, clean and consolidated.

- The metal parts to be anchored must be clean and free of grease, oil or rust.

- Drill (without percussion) the indicated size (See table 3: “Parameters for placement on hollow supports”).

- Insert the sieve into the hole.

APPLICATION OF THE CHEMICAL TACO:

- Remove the cap and screw on the static mixer.

- Put the cartridge in the gun. Press until a homogeneous gray color is obtained.

- Insert the nozzle to the bottom of the sieve.

- Completely fill the hole from the bottom to the surface.

- Insert the element to be anchored turning it slowly to avoid the formation of air bubbles. The manipulation/adjustment of the anchor must be carried out before the curing start time. (See section Technical Data_Curing Time).

- Apply the load (See table 4: “Recommended resistance (kN) on hollow support”), after the complete curing time (See Technical Data Curing Time section).

TABLE 3: PLACEMENT PARAMETERS ON HOLLOW SUPPORT

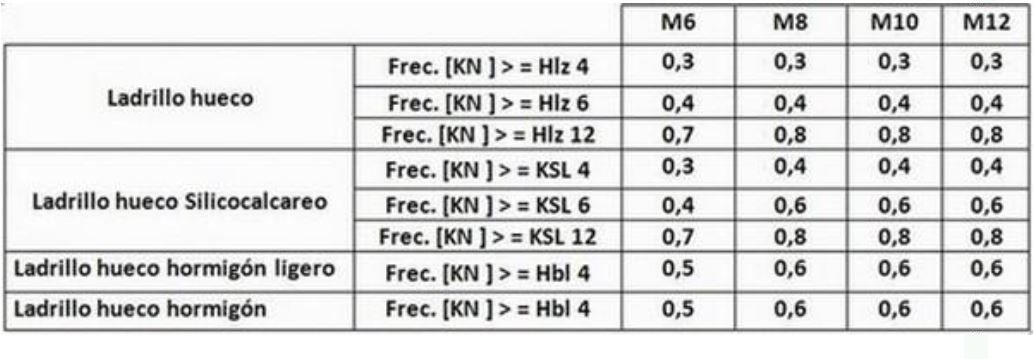

TABLE 4: RECOMMENDED RESISTANCE (kN) ON HOLLOW SUPPORT

Note: 1kN = approx. 98Kg (strength)

SECURITY:

Contact with eyes and skin should be avoided. Wear suitable clothing and gloves for eye and face protection. For more information, request the product’s Safety Data Sheet.

IMPORTANT:

This information is based on our practical experience and laboratory tests. Due to the diversity of materials on the market and the different forms of application that are beyond our control, we remind you of the need to carry out practical tests and sufficient controls in each case to guarantee the suitability of the product in each specific application. Our guarantee extends only to the uniform quality of the batches supplied, which are subjected to strict analytical controls, and no other responsibilities can be demanded.

Source: Free Basic Manuals