.

All about Epoxy resinsToday’s article is somewhat more technical than usual. But the occasion calls for it.

Today we want to talk to you about the characteristics of Epoxy resins, since their great versatility and their unmatched technical characteristics make It can be used for countless industrial applications, but also for DIY.

An Epoxy Resin or polyepoxide is a thermosetting polymer (the resin) that hardens when mixed with a catalyst or hardening agent. The most common epoxy resins are the product of a reaction between bisphenol-a and epichlorohydrin, bisphenol A is obtained from phenol and acetone. Epoxy resins are commonly made up of two components that are previously mixed before being used; When mixed, they react causing the solidification of the resin. They are cured at room temperature. During this curing or drying, cross-links are formed, which makes their molecular weight high.

Source: SuppliesParaKnives.com

Characteristics of epoxy resins

– Wetting and adherence are optimal.

– Good electrical insulation.

– Good mechanical resistance.

– They resist humidity.

– They resist the attack of corrosive fluids.

– They resist high temperatures.

– Excellent chemical resistance.

– Little shrinkage when curing.

– Excellent adhesive properties.

Applications

Depending on the molecular weight, epoxy resins can have many applications, from adhesives to coatings for cans and drums, among others:

– Paints and finishes

– Adhesives

– Applications of epoxy resins in the construction industry: Epoxy resins are used in the construction industry to join blocks and as mortar in buildings, as well as bonding between concrete, mortar, joints, membranes, anchors, paints and structural repair. .

– Composite materials

– Electrical and electronic systems

– Consumption and nautical applications, and in structural parts in aircraft.

– Industry

Presentation

The presentation of epoxy resins for sale comes in a wide range, from low viscosity liquids to high melting point solids and powders.

Epoxy paints and finishes

Epoxies are widely used in printing layers, both to protect against corrosion, acid and chemical attack and to improve the adhesion of subsequent layers of paint; Due to their high density, they handle a very limited color chart. Its surface finish generally tends to be semi-gloss, but becomes matte over time. Among its uses are: For exterior and interior surfaces in the protection of metal, wood, concrete or asbestos-cement, fumes, dust, splashes and spills of aliphatic solvents, for coastal areas and marine environments. Inside and outside of pressurized water pipes, buried or exposed, for hull bottoms (as barrier paint), painting of industrial or high-traffic floors, for tanks, submerged steel structures, machinery and equipment in industrial environments highly aggressive, when exposed to the atmosphere they chalk and yellow over time, so care must be taken and if necessary, cover with a gel-type paint if necessary.

Origin: Doepa

Epoxy Adhesives

They are two-component reactive adhesives that set by chemical reaction between an epoxy resin and a hardener, when the two components are mixed. Epoxy adhesives are characterized by having excellent resistance to chemical agents, heat and humidity, as well as great resistance to breakage in traction and shear. It is common to use them in the aeronautical and aerospace industry, in the manufacture of cars, bicycles, skis. They are used to adhere a large number of materials, including some plastics, and are marketed rigid or flexible, transparent or coloured, fast or slow drying.

If an epoxy adhesive is dried with heat, it will be stronger than if it is dried at room temperature.

Origin: Construction Theory

Epoxy resins for the manufacture of composite materials

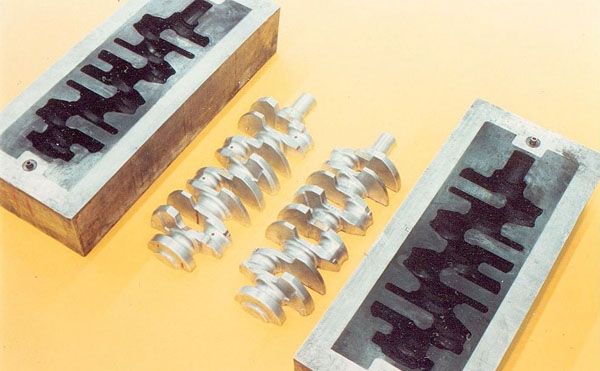

It is the mixture of epoxy resins with fibers, commonly fiberglass or carbon, this mixture is used both in the manufacture of molds and master pieces, laminates, extrusions and other industrial production aids. The results are cheaper, stronger and faster to produce than those made of wood, metal, plastic, etc. produce stronger parts. They are also widely used in sculpture, manufacture of prefabricated pieces and for reinforcement of recovery of construction elements of great value.

Origin: Direct Industry

Epoxy for electrical and electronic systems

Epoxy resins behave as excellent electrical insulators and are used in many electrical components and joints, to protect against shorts, humidity, dust, dirt, etc.

Epoxies in the electronics industry are used for the encapsulation of integrated circuits and transistors, they are also used in the manufacture of printed circuits.

Epoxy in nautical applications

They are also sold in nautical stores for boat repair and restoration.

Their price is generally high, although their development and popular uses make them more and more accessible.

Properties

The high number of epoxy resins and hardeners give rise to a wide range of properties in the different products. However, it is possible to expand this range with the incorporation of so-called modifiers, which will enhance the versatility and usefulness of epoxy resins.

The most common modifying agents are:

thinners

They allow to reduce the viscosity of the formulation, facilitating its application and increasing the capacity for the content of inert fillers. They can be inert or reactive. Inert, or non-reactive, diluents reduce viscosity appreciably. The solvent remains in the cure but is not chemically bound to it. Reactive thinners are the most widely used. They are usually monoepoxy compounds, such as epichlorohydrin itself, which react with the system, remaining chemically bound to it.

Flexibilizers

Whose mission is to reduce the rigidity of the system and allow it to deform under load. Flexibility can be achieved by introducing long chains covalently bonded to the network during curing, or by incorporating long molecular chains into the polymer that remain unreacted with the transformed resin.

loads

Used to reduce or improve some properties of the formulation. They are usually incorporated in the resin or in the hardener. Sometimes they can account for up to 80% of the final product, hence their importance. Its nature is very diverse, it can be silica, quartz, graphite, barium sulfate, fiberglass, etc., being the fillers with rounded granules the ones that suppose the minimum formulation consumption. Within the loads, the thixotropic agents give the formulation a structure capable of withstanding high shear stresses, preventing sagging. The most common are mica, bentonites or fiberglass.

pigments

Whose mission is to improve the appearance of the formulation with various colorations. Inorganic pigments can be used, such as titanium oxide, carbon black, chromates; or dyes, phthalocyanine blue and green. The modification with other resins enhances the possibilities of epoxy resins, by combining the advantages of different systems. This is the case of polyester and acrylic.

Source: allstudies.com Y School of Industrial Engineering

.

You may also be interested in these other technical articles:

the luminous paper |

Advantages of LED lighting |

Wood flooring designs |

How to install a sink |

.