If you thought that electric saws were going to displace, and even make traditional manual saws disappear, you are completely wrong.

You do not believe me? So, she keeps reading.

Many of the tools that have been used since time immemorial. An example of this can be manual carpenter’s planers, chisels, gouges and, of course, different kinds of manual saws.

In any cabinetmaking workshop, that is, high-level carpentry, in addition to power tools, they have many other hand tools, since they guarantee a much more controlled work and an impeccable finish.

Power saws, whether stationary or portable, are often used for large cuts and the toughest jobs.

However, in smaller jobs, but in which greater precision is required, it is highly advisable to resort to certain manual saws.

On this website you have a selection of electric and manual saws, which is worth taking a look at.

For all these reasons, this article will focus on a specific type of manual saws.

Main types of hand saws

In the first place we will see the main types of manual saws, which we can group into four large segments.

universal saw

The universal wood saw is one of the most widespread types of manual saws. Even if you are not a carpenter or a DIY enthusiast, it is very possible that you have one.

This type of saw has a large, strong blade that is used to manually cut wood, both crosswise and lengthwise. This is thanks to the arrangement of its teeth, which is such that it cuts in both directions.

rib saw

The rib saw is similar to the universal one, but with some differences.

Rib saws have a shorter blade and plus slim. For this reason, they have a reinforcement on their upper edge, hence their name, to prevent the blade from bending during the cutting process.

These types of saws have the finest and closest teeth, thus the cuts obtained are cleaner. The smaller and more numerous the teeth, the finer the cut.

They are designed for cross-cutting wood, with a precise and impeccable result.

The depth of cut is limited to the width of the blade, since the rib itself acts as a depth stop.

We can find two variants:

Straight rib saws

This type is ideal for miter cutting strips, moldings, skirting boards, etc., as well as for making straight or dovetail ties, since these types of joints require great precision.

Angled saws

We can also find angled and reversible rib saws.

This mode allows you to cut flush with the wall or floor. It also allows cutting to the left and to the right, thanks to the tilting movement of its handle that allows it to be fixed on one side or the other of the blade.

It is indicated for the lower recess of door frames for the installation of floating flooring and parquet.

Here I leave you this comparison of saws and rib saws, where you can find models for all needs.

point saw

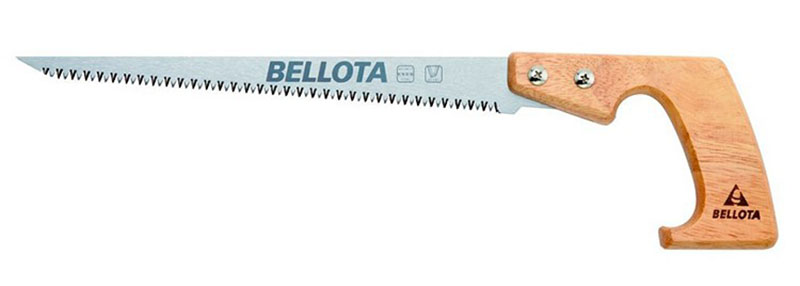

The point saw is similar to the universal saw but the blade is much narrower and ends in a point.

With large teeth, its cut is not as fine as in the case of rib saws. And one of its most common applications is plunge cuts in laminated plasterboard.

precision saws

Finally, we have the precision saws. Some of the most prominent are the Japanese saws. They are very similar to the rib ones, with small and numerous teeth, a very fine blade and quality finishes. However, there are two clear differences.

On the one hand, the cut direction. The Japanese cut when pulling the saw, however the first ones cut when pushed.

And on the other, that the Japanese blade they do not have why necessarily have rib. Precisely the cutting direction makes this possible without the danger of the blade bending or being damaged during work.

Security

We could not finish this article without including a section with the main safety measures that must be taken into account when using a manual saw.

- Use of gloves. Although on the surface, a handsaw may not seem too dangerous, it is. Its sharp teeth, the speed it picks up during the cut and the force we project, in an oversight could cause us very serious injuries. For this reason, the use of gloves and extreme care is highly recommended.

- The piece on which we will work must be perfectly attached to the workbench. In this way we will avoid sudden and unforeseen movements that are normally the cause of accidents.

- We must always keep our hands out of the cutting path of the blade.

- Use of mask. Wood cutting, whether mechanically or manually as is the case, releases particles that remain in suspension and are harmful to the lungs in the long term. Therefore, it is advisable to protect our respiratory tract.

.