The grinder is a highly versatile and versatile electric tool, small in size, and very easy to use. The latter does not mean that, when using it, we keep in mind a series of safety regulations.

This tool is capable of machine practically any type of material; from steel to ceramic, through bone. In fact, in one of our latest crafts we have used a grinder for machining seashells easily and quickly. Here you can see the grinder in action.

The indicated characteristics make this tool indispensable in any mechanical workshop, carpentry, metalwork, and even in many DIY hobby workshops.

That said, let’s get into the types and uses of grinders.

There are various types of grinder and it should be clarified that, depending on the country or geographical area, this tool is also known as a grinder, electric emery, stone or emery stone. Whatever its name, it is another abrasive machining tool that uses a grinding wheel driven by an electric motor. This is the same principle as a grinding machine, but the fundamental differences between a grinder and a grinder lie in the fact that the grinder it is a much simpler tool and in which, since it is not intended for finishing parts, the cutting effort is much higher than that of a grinding machine.

According to the general classification we can highlight four types of grinder:

angle grinder. It’s basically a angle grinder.

belt grinder.

bench grinder.

pedestal grinder.

There are also special grinders, such as the grinder of tube ends, which is used to clean tube ends and plate edges quickly and easily. They have two small wheels that can be adjusted to the desired wall thickness and are used for metalwork, appliance and heater construction, shipyards, mechanical engineering, and piping, among others.

.

belt grinder

Belt grinders in their bench format are usually a combination of grinder and belt sander, as shown in the following figure.

Belt Grinder

However, there are also double band grinders. In this type of tool, the cutting operation of the material is carried out by an abrasive band, so the mechanism is ideal for irregular and even cylindrical pieces, such as pipes or tubes.

There are also much more sophisticated belt grinders, like the one we can see in the following video, with an interesting application.

.

bench grinder

It is, in general, a machine of small dimensions and about 6 or 7 kg in weight, which is mounted on a workbench and is used for sharpening tools (drill bits, chisels, lathe blades, screwdrivers, chisels, etc.). chisels, etc.) and for removing burrs from small parts. It has two wheels of different granulometry on each side, a fine one for sharpening and another one more enough to go over.

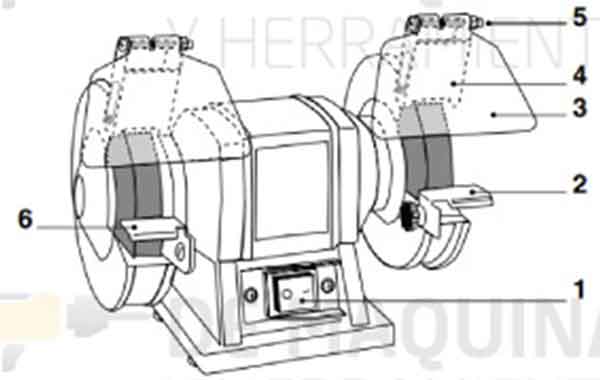

Bench grinder parts

The main components of a bench grinder are:

- Ignition switch.

- Tool holder (right).

- Eye protection.

- Eye shield clamp.

- Screw.

- Tool holder (left).

Bench grinder uses

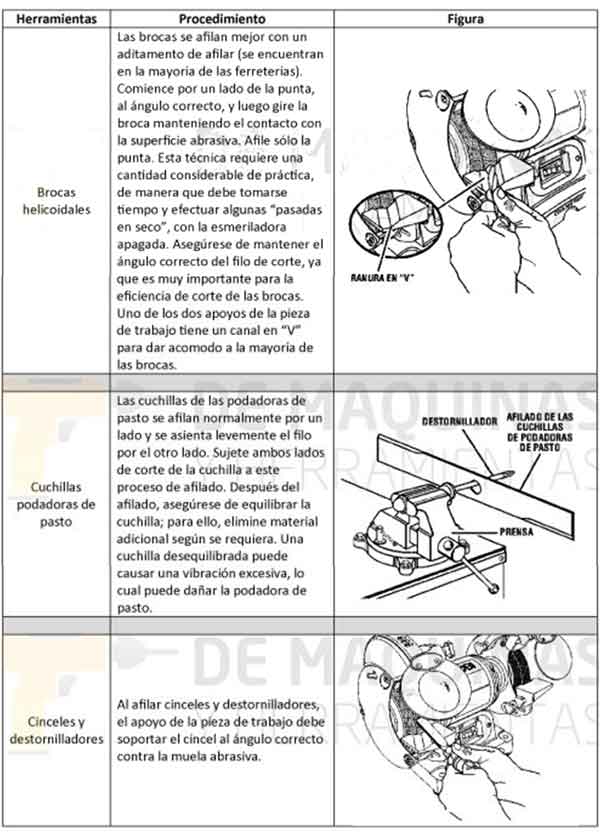

The following table shows some examples and procedures for tool sharpening with a grinder from bank

.

pedestal grinder

Many bench grinders come with a pedestal as an optional part, which does not mean that they can be “transformed” into a stand. pedestal grinder. In contrast, pedestal grinders themselves are larger, heavy-duty tools. They are used for cleaning welds and for removing burrs from castings and other large parts.

Pedestal Grinder

They consist of a cast-iron pedestal or base that is screwed to the floor and feature the same components as a bench grinder, but the assembly of the grinding wheels is much more robust, they have a light and a central command in the upper part. Some models incorporate a duct finished in a cloth bag, where the particles detached from the machined material and from the grinding wheels are collected. They can also contain a container of water to cool the tools.

Depending on the power, size and speed of rotation of the grinding wheels and the spacing between them, there are pedestal grinders from 1/3 HP to 5 HP, corresponding to rotation speeds of 3600 RPM for the less powerful model and 1200 RPM for the 5 HP.

.

Precautions with the use of grinders

Although equipped with safety guards and other effective features, grinders are dangerous tools that must be used with extreme caution. Before use, the tool’s instruction manual should be read carefully. in our article Security Measures in DIY You have a series of safety regulations applicable to the use and handling of any power tool. And, to avoid accidents and unnecessary risks, never forget the most important safety rule: the sense common.

In addition, other additional care must be observed with the use of the wheels, such as those detailed below.

The wheels must be properly surrounded by protectors of tenacious material.

They should fit snugly on the axle, but in no case should they be too tight.

Take care that the machine shaft rotates in bearings with free play and that it does not hit.

When starting the grinding wheel, try to gradually reach the necessary number of revolutions.

In the first start-up and especially when the grinding wheel is uncovered or poorly protected, be careful not to stand in front of it.

Protect the grinding wheel against knocks.

The grinding wheel overheats when sharpening. This heating should not occur too quickly. If a cold tooth is subjected to very fast and strong stress, it can break, especially in winter temperature conditions.

If the wheel must be stressed very strongly on its sides, try to use a coarse grain size. If lateral work is continuous, shape wheels should be used.

Origin: From Machines and Tools