In this article we will talk about a material whose behavior is excellent in places where there is a high degree of humidity. We are referring to compact phenolic panels.

But before looking at the many advantages of phenolic panels, we will start by looking at what exactly they are. And to see what they are, and in order to avoid confusion, we have to distinguish between phenolic plywood boards and compact phenolic panels.

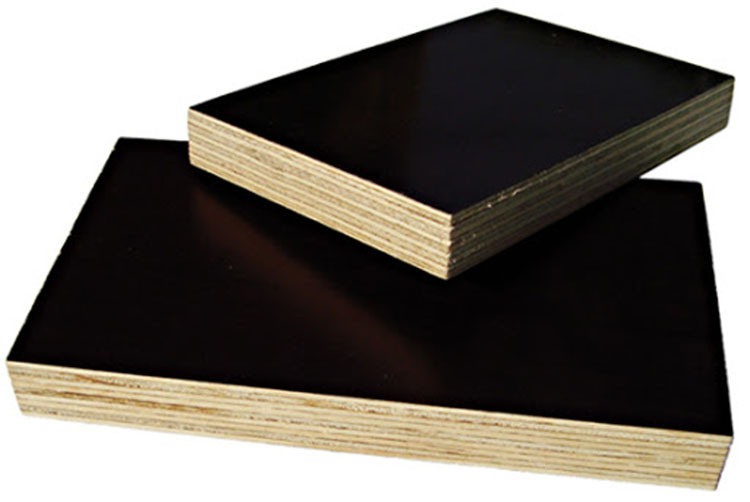

Phenolic plywood boards

Plywood boards are made up of different sheets of wood glued together and arranged crosswise between each other, which gives it enormous stability and resistance.

Well, in the phenolic plywood board, phenolic glue is used for the cohesion of the different layers of wood. Hence its name.

Birch is one of the most used woods to make this type of boards.

Normally we can find this type of boards covered in different finishes, such as with plasticized outer layers and non-slip outer layer, among others. The density of this type of board is usually between 550-700 kg/m3, depending on the wood used.

Among its most frequent uses we can mention formwork, stages, and vehicle bodies.

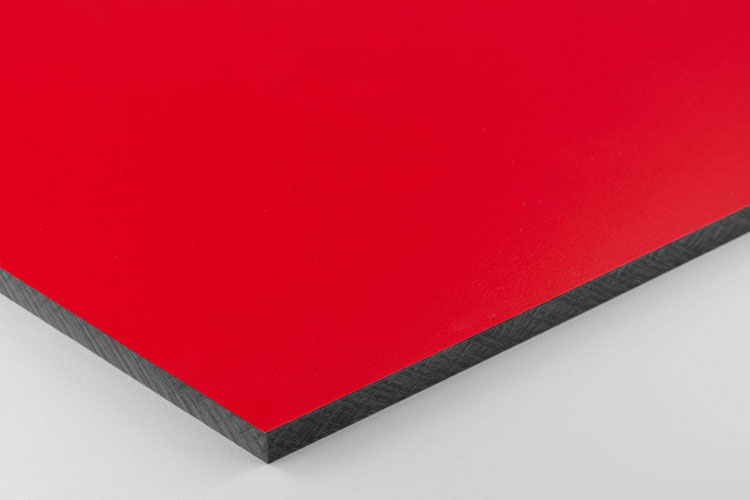

Compact Phenolic Panels

We can broadly say that phenolic panels are made up of a core of phenolic resins with thermosetting cellulosic fibers, achieving high density. This compact core is “dressed” with coatings of different materials such as laminates and natural wood veneers, thus achieving highly aesthetic finishes.

Characteristics of compact phenolic panels

As we have said, it is a high-density fiber compact, normally around 1,000 kg/m3.

The compact phenolic panel is very hard and resistant, has low thermal conductivity, low formaldehyde content, is resistant to bending, is antibacterial, has very good dimensional stability, excellent behavior against humidity and fire and, above all, its great durability, are some of the main characteristics of compact phenolic panels.

Uses of phenolic panels

The core of the high-density panel, made up of resins and fibers, makes this type of panel very suitable for furniture that is highly exposed to humidity.

In fact, it is a material widely used in particularly humid environments such as bathrooms and toilets, changing rooms and kitchens.

In addition to their enormous durability, they are antibacterial thanks to their low porosity. Aspect, the latter, of great importance in environments laden with humidity.

Although below we will see several of the most recommended applications, the phenolic compact for public toilets is the most indicated.

Phenolic panels are suitable for both interior and exterior use.

Indoor uses

Among its numerous and diverse uses, we can highlight the following:

- Lockers and changing rooms in gyms and sports facilities.

- Sanitary cabins, including partitions and doors, in public toilets.

- Countertops in kitchens and bathrooms.

- Hospital and hotel equipment.

Outdoor uses

Among other uses that are given to phenolic panels we can highlight, on the one hand, hotel furniture such as tables, chairs and bar tops outside. And on the other, the cladding of building facades.

.